Production leaders in chemical formulation-based batch manufacturing constantly face these problems but struggle to find a permanent solution:

- Excessive cycle times

- Batch to Batch Variability

- Lower than optimal yield

- Waste & recycling of off-spec product

- Production loss during product and grade changes

Engineering teams struggle to address production leaders' challenges with minimal data context available from existing MES and control systems.

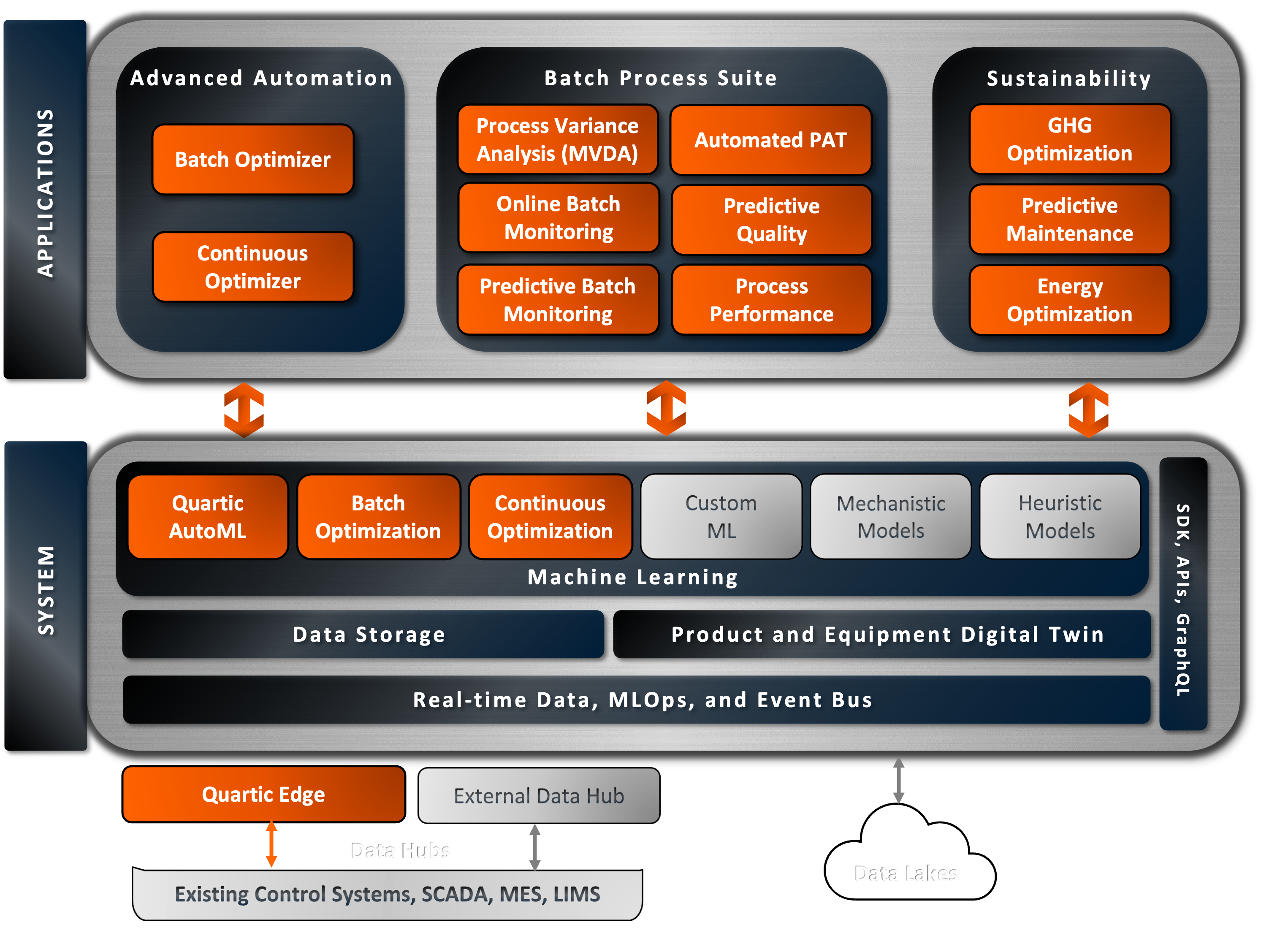

Quartic’s AI-enabled digital batch manufacturing system eliminates these problems and provides a supervisory multi-variate batch optimization system to produce incrementally improving production outcomes.

“With Quartic’s Digital Batch Optimization system, our batch variability was reduced by 49% and with much tighter controls we gained back 17% of lost cycle time on our fermentation unit”

“It took us two weeks to contextualize our PLC, operation logs, and MES data into Quartic, and deploy real-time multi-variate monitoring of a production line, allowing us to identify bottlenecks, reduce variability, and provide operator guidance to maintain on-spec product”

The Quartic end-to-end, multi-variate batch monitoring and optimization system empowers manufacturing technology and continuous improvement teams with these capabilities.

Capabilities you will achieve by using this system:

- Ready to use contextual batch data – real-time and historical

- Product, batch, and multi-unit views for analysis

- Historical batch analysis

- Realtime multivariate SPC and Machine Learning

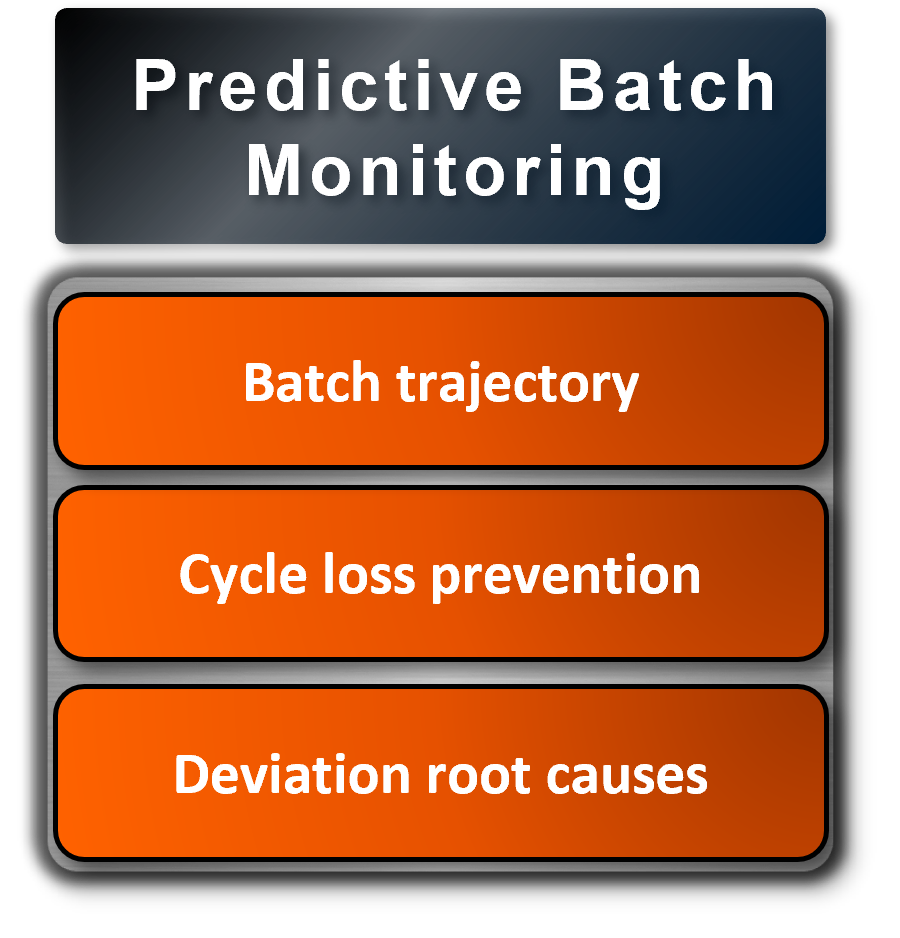

- Predictive Batch evolution trajectory

- Realtime parameter influence indication

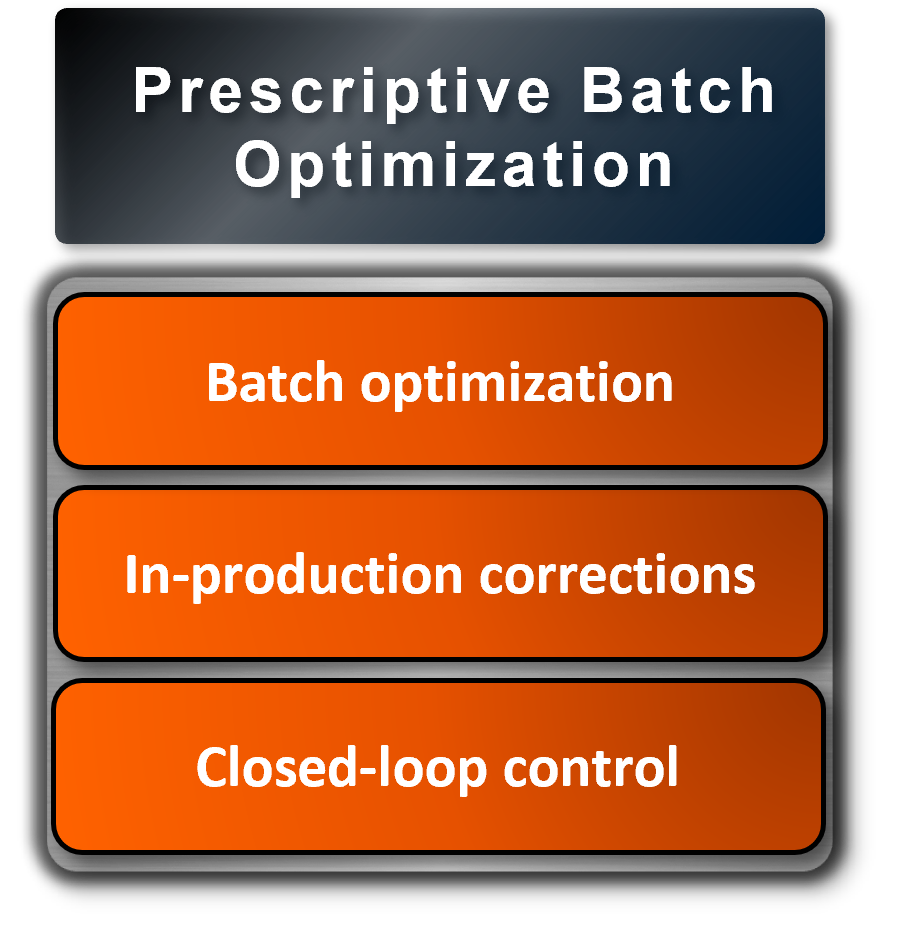

- Supervisory Closed loop multivariate control

Using these capabilities Batch Process Manufacturers can move from process control systems and manufacturing management systems to a Manufacturing Operations Automation system

Manufacturing Operations Automation for Digital Batch Manufacturing

- Control System & MES Agnostic

- Cloud native & Agnostic

- Production line to enterprise scaling

- ISA99, IEC62443 ICS security

- IS9001, SOC2

- Simple licensing – no user limits, no interface limits