In batch manufacturing, optimizing processes for consistent yields and quality standards remains a top priority. Yet, the intricacies of batch operations often pose challenges in identifying and mitigating variability. Enter advanced analytics technologies, offering a transformative approach to streamline operations and elevate performance.

Harnessing Multivariate Analysis for In-Depth Insight

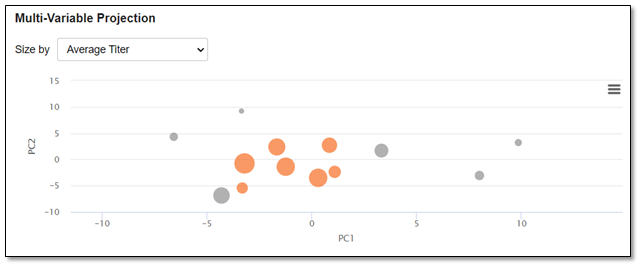

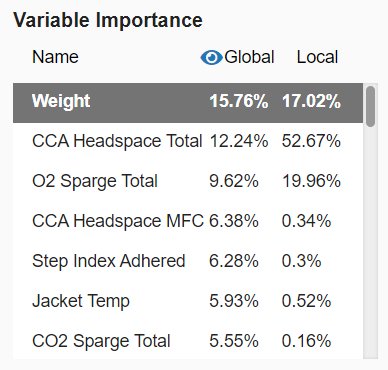

As seasoned process engineers know, uncovering the root causes of variability is paramount in batch manufacturing. Advanced analytics, particularly multivariate analysis, empowers engineers to delve deep into historical batch data.

By dissecting multiple process variables simultaneously, patterns and correlations previously obscured by traditional methods are revealed. This allows engineers to pinpoint critical parameters influencing yield and prioritize optimization efforts.

Real-Time Monitoring: From Reactive to Proactive Control

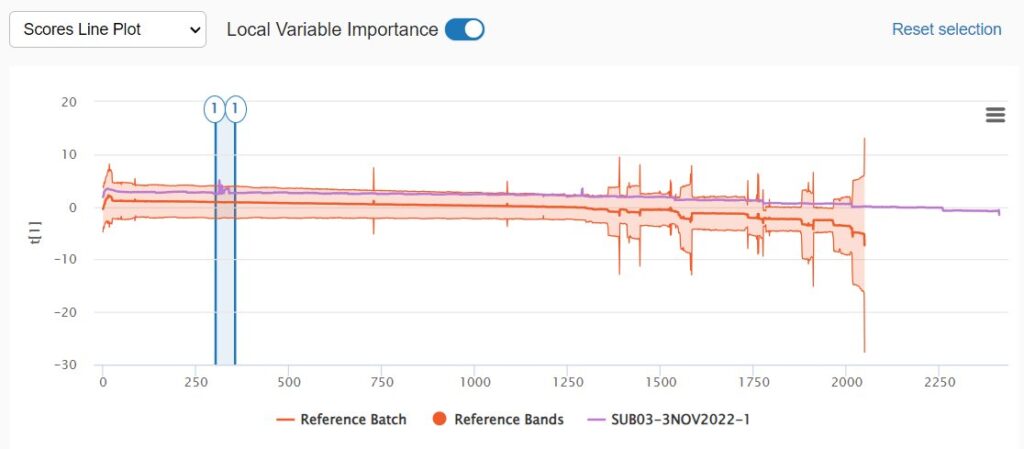

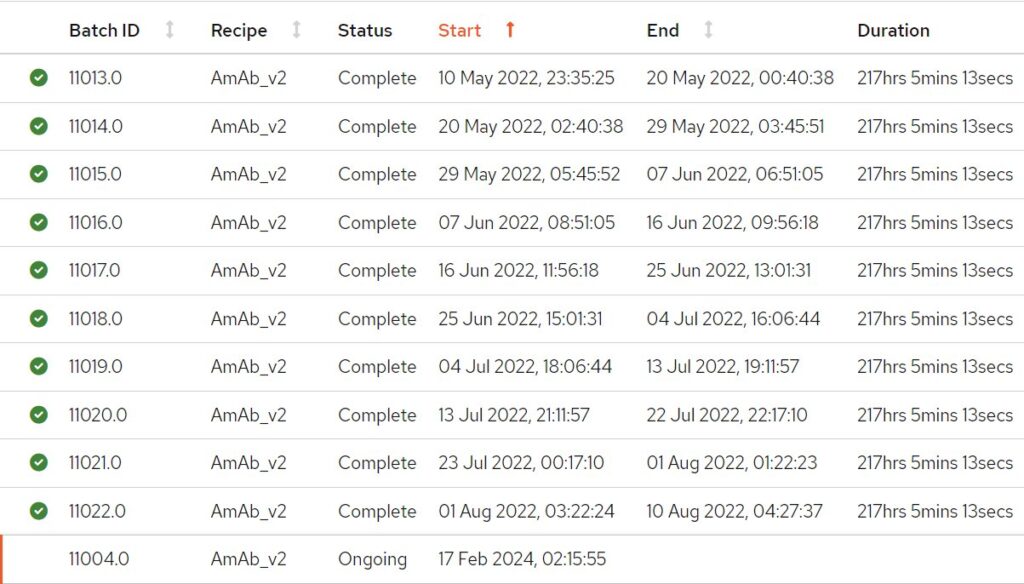

Historical data analysis lays the groundwork, but real-time monitoring is the cornerstone of proactive decision-making during batch runs. Advanced analytics platforms equip process engineers with the tools to monitor operations in real time, enabling comparison against predefined targets or reference batches.

Leveraging machine learning models, deviations from expected yield trajectories are quickly identified, triggering proactive interventions to mitigate potential issues. This transition from reactive to proactive monitoring empowers engineers to maintain stringent process control and preempt yield loss effectively.

Predictive Analytics: Anticipating Future Outcomes

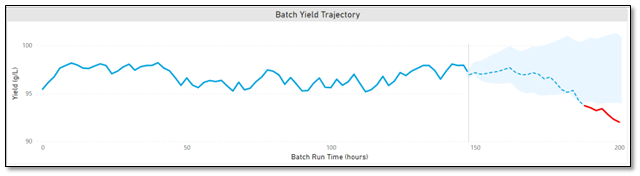

Taking real-time monitoring to the next level, predictive analytics allows manufacturers to anticipate future batch outcomes and take preemptive action. By harnessing historical and real-time data, predictive models forecast yield profiles and anticipate deviations from optimal performance.

Armed with this foresight, operators can intervene before issues escalate, ensuring batch runs remain on track to meet desired outcomes. Predictive analytics also enable scenario analysis, empowering engineers to evaluate the impact of process adjustments on yield and make informed decisions accordingly.

Seamless Integration with Modern Data Platforms

The effective implementation of advanced analytics hinges on seamless integration with modern data platforms. These platforms serve as the backbone for data collection, contextualization, storage, and analysis, facilitating cross-functional collaboration and access to data-driven insights.

By consolidating disparate data sources and leveraging cloud-based infrastructure, manufacturers can fully harness the capabilities of advanced analytics while ensuring scalability and flexibility in operations.

Conclusion: Driving Operational Excellence Through Advanced Analytics

In the pursuit of operational excellence, advanced analytics emerges as a necessary tool for process engineers in batch manufacturing.

By harnessing the power of multivariate analysis, real-time monitoring, and predictive analytics, engineers gain unparalleled insight into process variability and control. Integrated with modern data platforms, these analytics solutions unlock new levels of efficiency and agility, positioning batch manufacturing operations for success in today’s dynamic landscape.

Embracing advanced analytics is not just a choice but a necessity for manufacturers striving to stay ahead of the curve and achieve operational excellence in batch manufacturing.

For a more in-depth discussion of this topic, as well as a demonstration of how the Quartic Platform and MVDA application solve these challenges, watch the related webinar below: https://www.youtube.com/watch?v=heY6AWZh1TI