Helping you do what you do

Current solutions based on traditional univariate statistical techniques and static rules-based systems fall short of meeting your business objectives, because your manufacturing operations data is multi-dimensional, non-linear, and continuously changing.

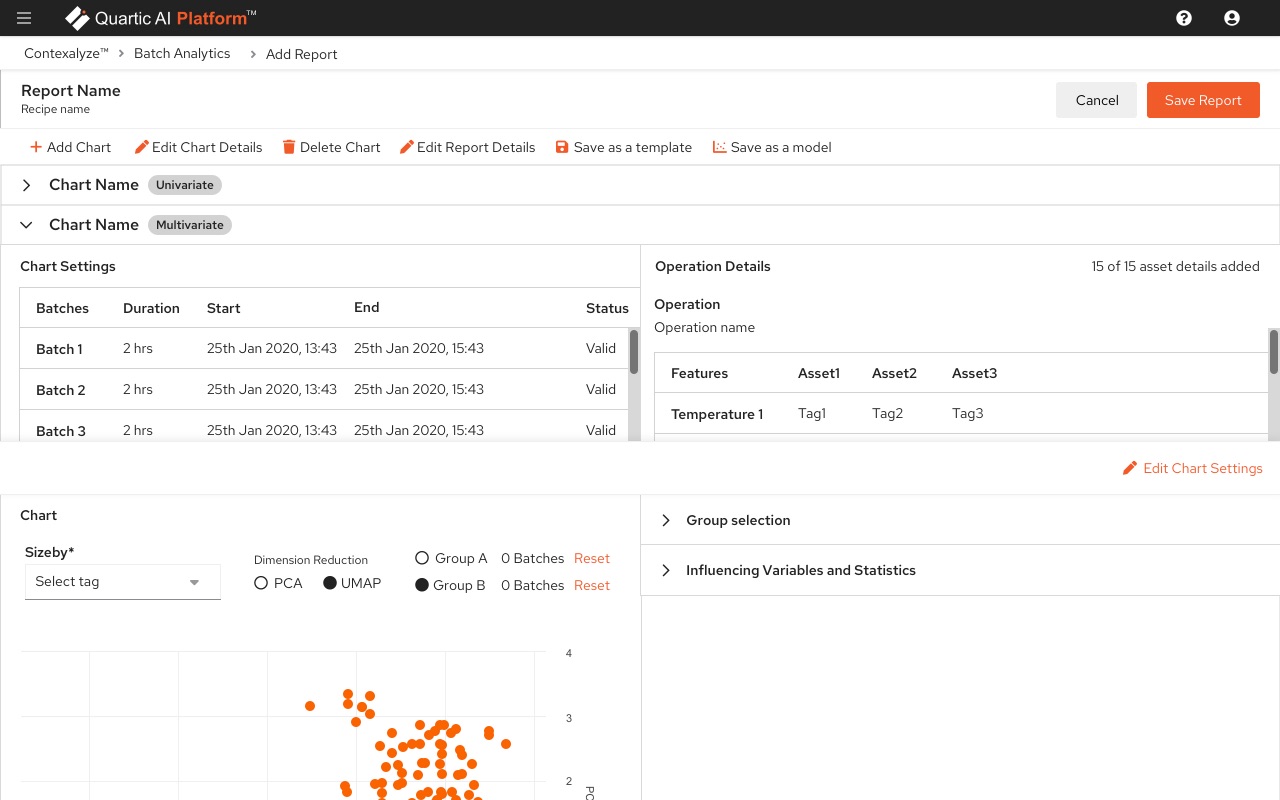

The solution: Q.Applications – Batch analyticsDesign the ideal batch process through predictive Multi-Variate Data Analytics (pMVDA) with purpose-built ML models that analyze and continuously learn from non-linear multi-variate relationships across repeated runs of your batch process.

Your current solutions integrate loosely or do not integrate all three - operational, planning, and control – time horizons, resulting in inferior operational efficiency and productivity.

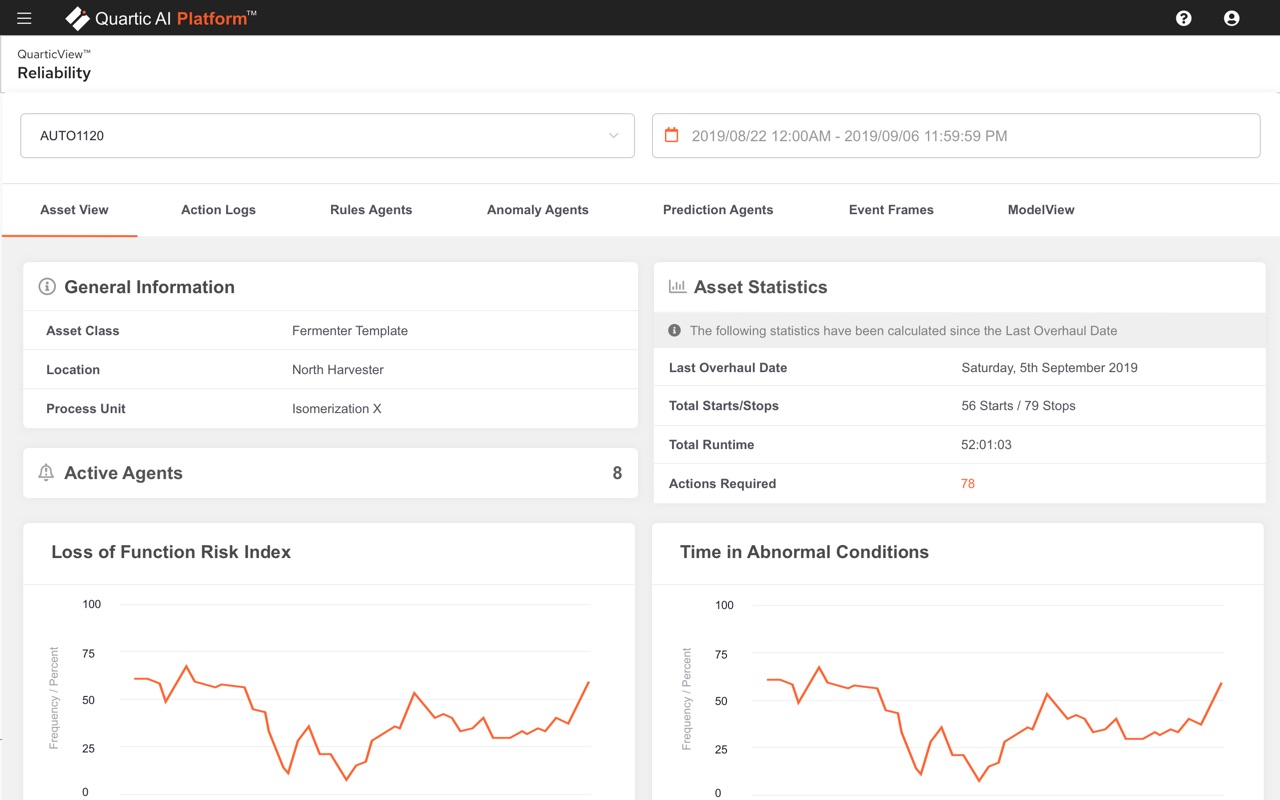

The solution: Q.Applications – APMKeep your assets running, without surprises, with intelligent Asset Performance Management (iAPM), combining industry-standard reliability principles, such as RCM, with machine learning-based predictive analytics.

Your current analytics solutions often take an either-or approach in choosing between first principle-based analytics or ML-based analytics resulting in loss of precious insights from the missed-out approach.

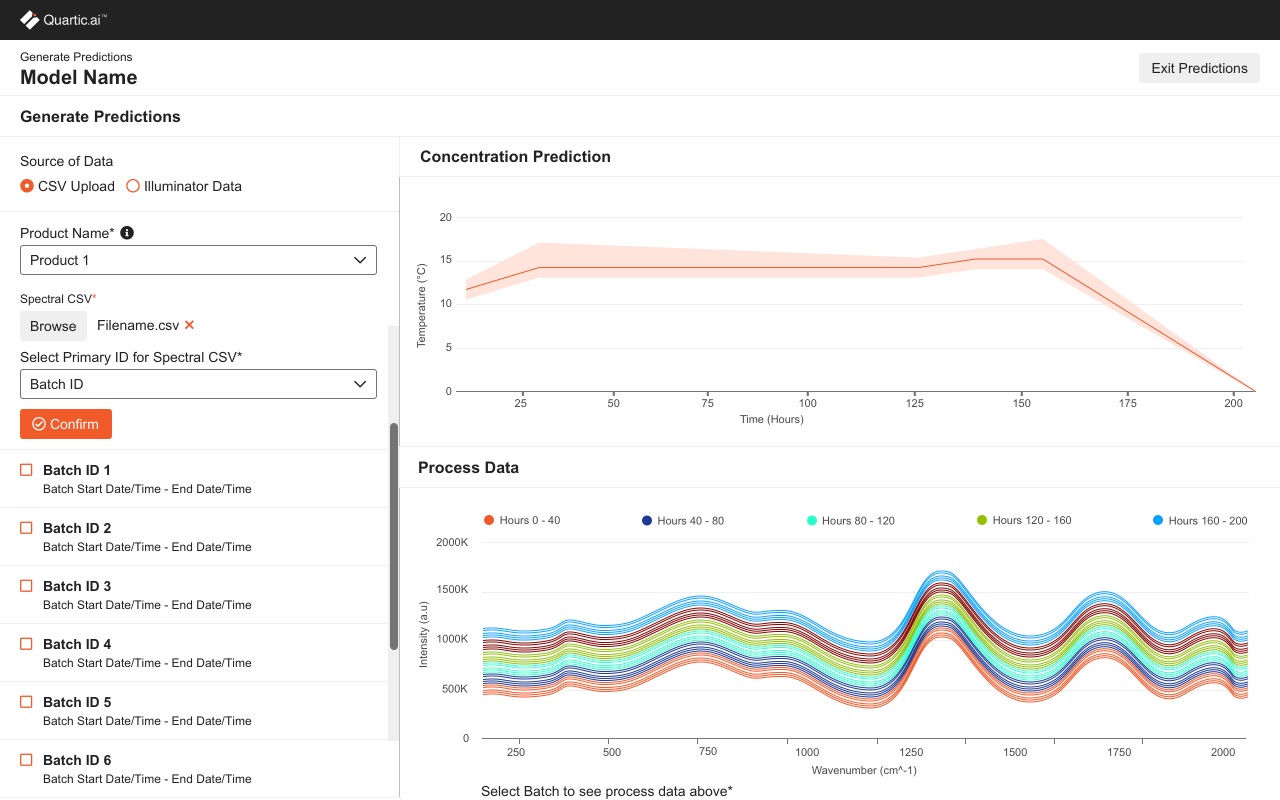

The solution: Q.Applications – PPVIdentify your process data deviations and autonomously execute process control strategies through the Product and Process Verification application.